- jiabao@csj-baler.com

- 0086 18721814932

- No.1,East Xinyuan Road,High-tech Park,Rugao,Jiangsu, China

In the golden autumn of October 2024, the China International Corrugated&Color Box Festival (October 10-12, 2024) was grandly held at the Tanzhou International Convention and Exhibition Center in Foshan. This is a two-way trip between Nantong Jiabao and industry customers, traveling from thousands of miles away and in all directions

At this moment full of opportunities and challenges, Nantong Jiabao Intelligent Packaging System has once again gained global popularity, showcasing its technological strength, hardcore products, and professional services to the world.

exhibition scene

On the second day of the exhibition, continuing yesterday's high popularity, customers at the Nantong Jiabao booth were enthusiastic, and the on-site passenger flow reached a new high. Change business cards, add WeChat, discuss solutions, talk about cooperation The lively and extraordinary negotiation scenes are everywhere, witnessing this industry event with unlimited business opportunities.

Nantong Jiabao actively showcases its strength and advantages in technological innovation, product quality, service guarantee, and other aspects to domestic and foreign customers. Through various methods such as on-site graphic and textual promotion, video playback, and technical exchanges, Nantong Jiabao has been introduced to customers from all over the world, and has had in-depth exchanges and negotiations with many potential customers.

Popular products

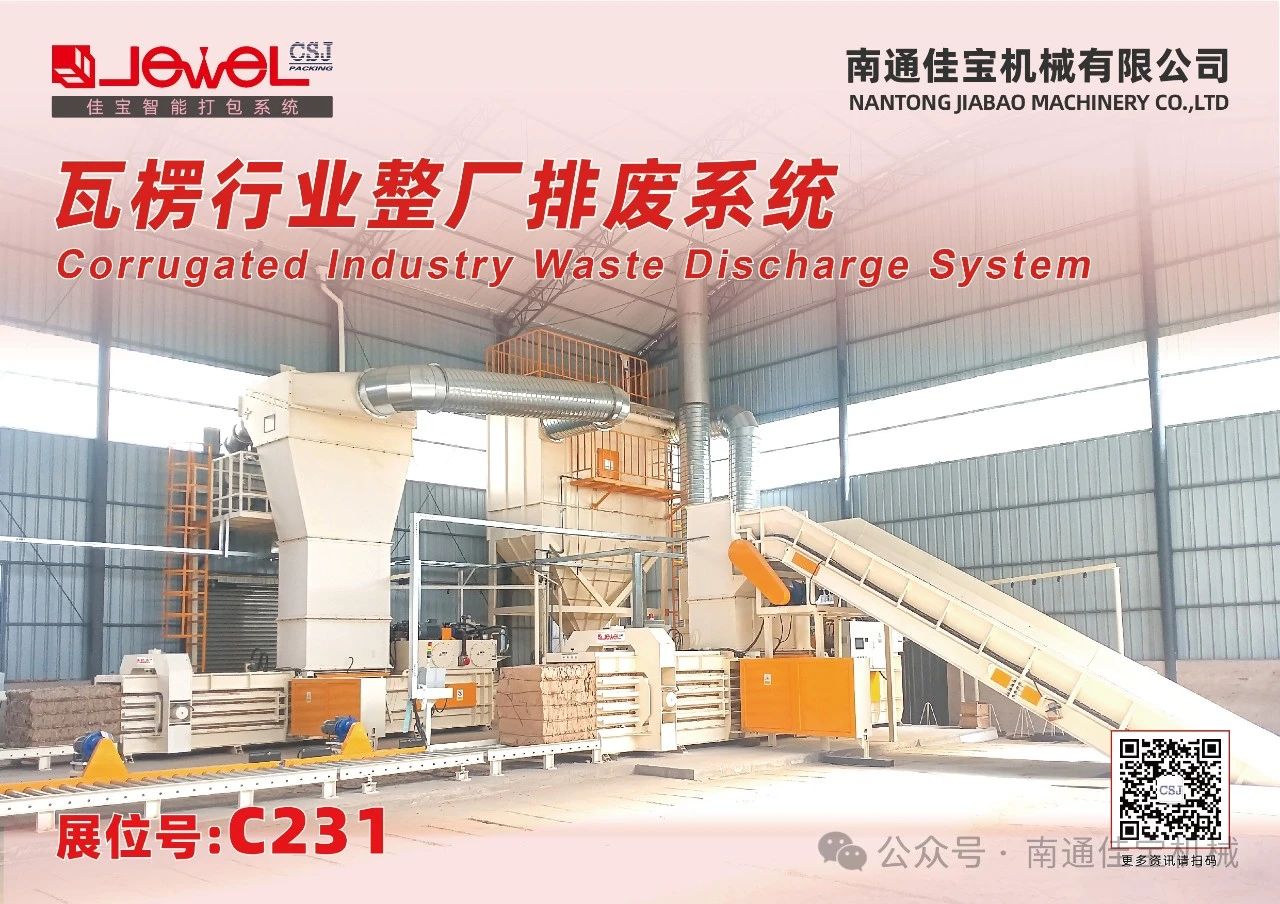

At this exhibition, Nantong Jiabao showcased a variety of popular models - corrugated packaging industry whole plant waste discharge system, color box printing industry whole plant waste discharge system, horizontal fully automatic compression packaging machine, horizontal semi-automatic compression packaging machine, vertical compression packaging machine and other equipment, all of which are intelligent and automated waste paper compression packaging solutions tailored for customers in the corrugated, printing and color box industries. They directly hit the pain points of customers' industries, making waste paper processing no longer a problem, greatly improving customers' production efficiency, and achieving cost reduction and efficiency improvement.

Whole plant waste disposal system for corrugated packaging industry统

01

The dust laden gas discharged from the paper gas separator is connected to the bag filter, and the dust removal rate can reach more than 98%. According to the customer's requirements, the upper exhaust cyclone separator can also be selected, and spray devices can be installed for simple dust reduction.

This set of equipment can be equipped with a package weighing system at the back end of the packaging machine, and can be connected to the production management system to manage production costs and waste paper volume online.

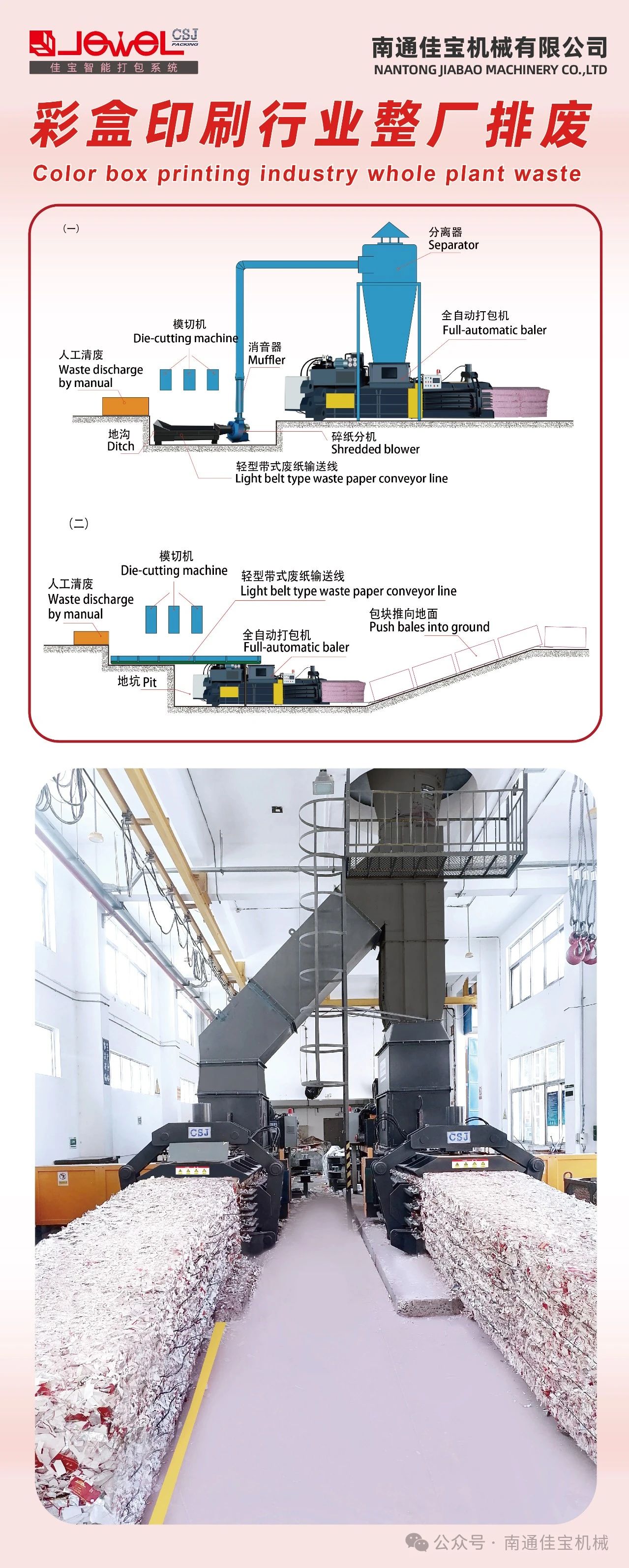

Whole plant waste disposal system for color box printing industry

02

Horizontal fully automatic compression and packaging machine

03

* Adopting a three sided closing and reverse pulling design, the oil cylinder automatically tightens and relaxes, providing stability and strength.

* PLC program with touch screen control, simple operation, built-in feeding detection, automatic compression, realizing unmanned operation.

* Automatic bundling device, fast speed, simple structure, stable operation, low failure rate, and easy to clean and maintain.

* Equipped with an acceleration oil pump and a booster oil pump, it saves electricity, energy, and costs.

* Automatic fault diagnosis, automatic display, improve detection efficiency, freely set package block length, accurately record packaging values.

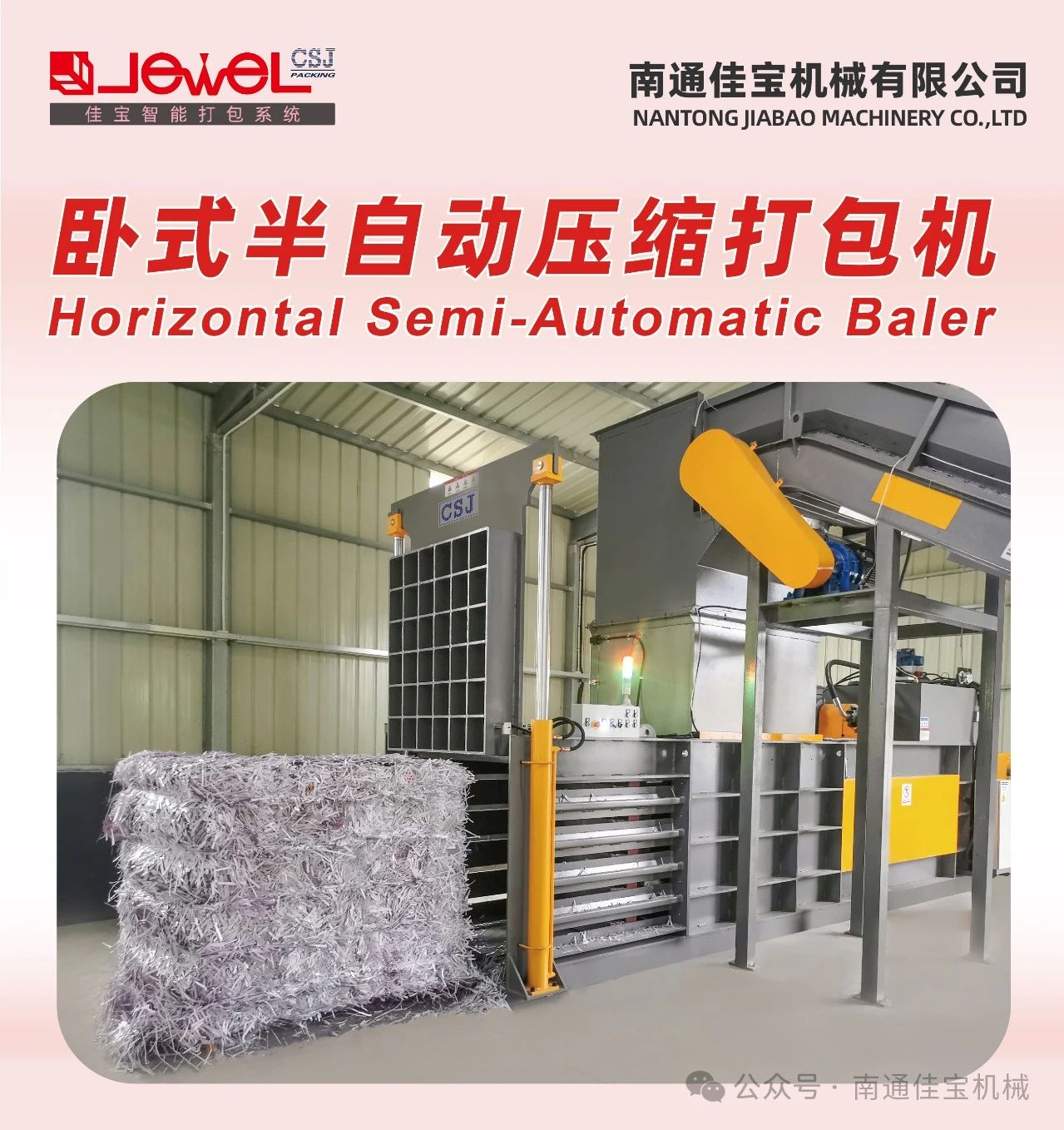

Horizontal semi-automatic compression and packaging machine

04

Suitable for recycling, compression and packaging of fibers, sponges, cardboard, PET bottles, hard plastics (such as computer cases, bumpers), etc.

* Closed hydraulic up and down lifting opening and closing door structure, allowing for one-time bag removal without the need to move the bag in a timely manner.

* High strength package door, dual cylinder automatic door opening and closing device, safe and reliable.

* The packaging length can be set and there is a bundling reminder device.

* Pre embedded design, each wire or bundling rope only needs to be manually threaded once to complete bundling, saving labor.

Vertical compression packaging machine

05

Suitable for the recycling, compression, and packaging of conventional materials such as waste paper, plastic, cardboard boxes, and waste, with strong model selectivity; Suitable for various domestic and foreign enterprises, logistics, and supermarket industries.

* U-shaped balancing device to avoid accidents caused by uneven feeding.

* The feeding port adopts a movable up and down design, with automatic door opening for convenient feeding.

* Safety interlock, with built-in flipping system.

* The feeding chamber adopts a device to prevent material rebound, greatly saving feeding time.

The strong product and brand strength have attracted the attention of many industries, making Nantong Jiabao the focus of attention in the exhibition hall. This exhibition not only showcases the strength of its intelligent packaging system, but also drives Nantong Jiabao to continue to forge ahead in the field of intelligent packaging equipment and contribute more to the sustainable development of more industry customers.